2016-05-04

Strong performance in just twelve weeks

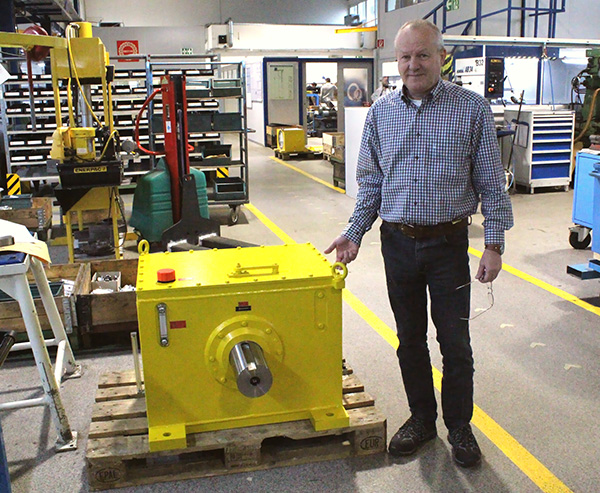

RINGSPANN realises its biggest housing freewheel yet in record time

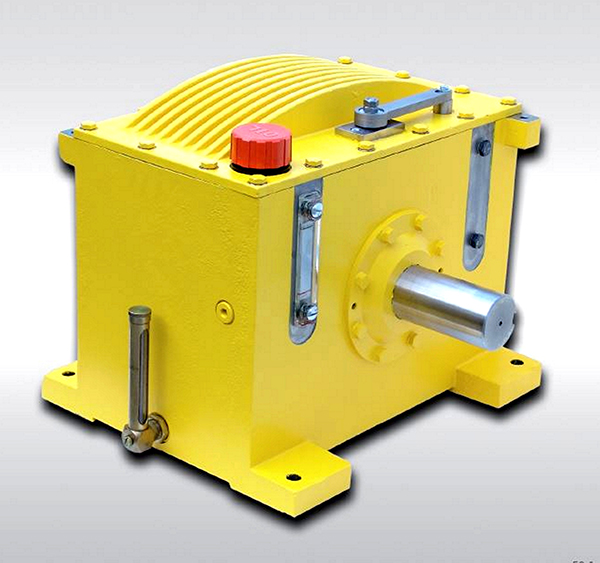

RINGSPANN has built its biggest and most high-performance housing freewheel to date for an Asian plant construction company. The extraordinary unit was shipped a few weeks ago and is now used by a chemical factory as an overrunning clutch in the drive system of a fan with oversized dimensions. With its nominal torque of over 40,000 Nm, the now biggest housing freewheel in the RINGSPANN portfolio sets international standards.

Bad Homburg, May 2016. – You could perhaps, with a little wink, put it this way: The next proposal for the Guinness Book of Records is from Bad Homburg. For a few weeks ago the drive engineering specialists of RINGSPANN, a company based in this town, presented their biggest and strongest housing freewheel yet under the type designation FH 30.000 R. Its crucial performance parameters of nominal torque and maximum torque capacity are, with 40,675 Nm and 81,350 Nm respectively, far above the previous maximum values of the RINGSPANN model FH 18.000 R (24,405 Nm/48,410 Nm).

"Excellent process management"

The FH 30.000 R was developed and manufactured by order of an Asian plant construction company. And RINGSPANN needed just twelve weeks from the initial enquiry to the delivery! "We were able to achieve this unusually short implementation time thanks to an excellent process management by all those involved in design engineering, purchasing, manufacturing, subcontracting and quality assurance", reports Thomas Heubach, manager of the freewheel division at RINGSPANN. The modular concept of the housing freewheels of RINGSPANN′s FH series has also made an important contribution to the quick development and manufacturing of the FH 30.000 R. And since it was a special individual solution in this case, the team led by Thomas Heubach decided in addition to execute the housing as a welded structure, which was quicker and easier to implement than the cast variant. In order to meet all approval requirements of the plant construction company, RINGSPANN had the housing certified in terms of tightness, welding engineering and connecting dimensions.

Housing freewheel instead of complex clutch

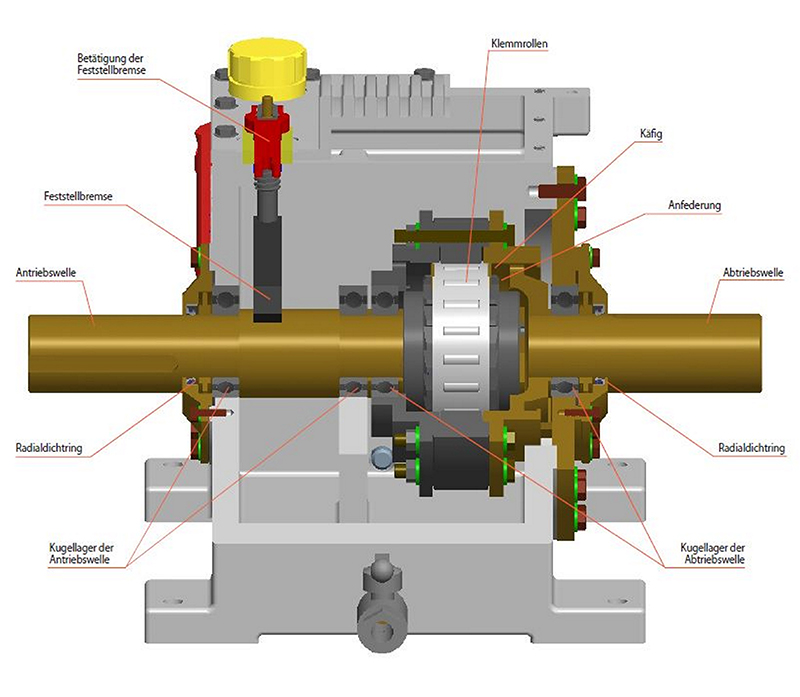

The large housing freewheel is used in a chemical factory, where, between a steam turbine and a powerful fan, it assumes the function of an overrunning clutch with a maximum overrunning speed of 2000 rpm. Division manager Thomas Heubach explains: "In the start-up phase, the fan is electrically driven at first, at which point our FH 30.000 R automatically decouples the turbine that is still stationary. While the plant is running, excess steam is then generated which is used for energy recovery. As soon as the steam pressure is sufficient, the steam turbine supports the electric motor – meaning energy costs can be noticeably lowered. “The decisive advantage is that, through using the overrunning freewheel by RINGSPANN, the installing of an expensive and complex clutch, which in addition would require complex switching, has become unnecessary. For the FH 30.000 R mechanically connects and disconnects the steam turbine speed-dependently and fully automatically – and you could almost say "naturally".

Low-maintenance and non-wearing

While it is running, the housing freewheel by RINGSPANN is characterised by a high reliability and low maintenance. As a closed system with an integrated oil filter system and integrated fixing brake, it needs no kind of external oil supply for example. And Thomas Heubach adds: "All our FH series housing freewheels work without wear thanks to their hydrodynamic clamping roller lift-off. Meaning the user just needs to remember to change the oil every now and then". Because of the hydrodynamic clamping roller lift-off in particular, the RINGSPANN housing freewheels of type FH are a preferred overrunning freewheel solution for stationary applications where a unit is to be driven by two or more engines or turbines with the same or a similar speed.

In the case of the housing freewheel FH 30.000 R, which could well be a record-breaking product, RINGSPANN′s services included, in addition to development and manufacturing, extensive test runs and the preparation of detailed test records for tightness and temperature stability.